- +621-5560-572 / 73

- sales@yamagen-power.com

- Mon - Fri: 7:00 - 15:00

TNV SERIES

Why TNV

The TNV series adds a whole range of "goodies" that make this engine a mechanical "Work of art"

The much acclaimed “Cleen and Silent” TNE series has just become even better. Its called the TNV, and it stands for Total New Value. Lets take a look.

Emission Reduction (ie a cleaner Engine)

Cleaner engines with even lower exhaust emissions are achieved by improving on the already excellent TNE base. Stricter emission standards are cleared by a wide margin.

IDI Engines

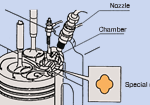

1. Combustion Chamber

By investingating flow charateristicc using experimental and numerical analysis methods, Yanmar research has archived improved flow mixing in both the main chamber and the special mouth surrounding the injector. More efficient use of the incoming air charge results in cleaner burn and lower exhaust emissions.

2. Fuel Injection Equipment Mechanical Pump

Instead of a PFR pump. a newly developed in-line pump has been used for the smaller TNV engines. Adjustment are made solely in the Yanmar’s own FIE factory ensuring precise compliance with regulations. Also the following features are incorporated :

- Increased force is applied by the governer to quicken the fuel controlling rack response time. Engine revs are more constant. Matching to a wide range of machinery is simplified.

- Emmisions have been reduced by controlling fuel injection timing according to engine load.

- Cam profile are matched to nozzle throttle needs, which give a better controlled injection rate. Emissions are reduced.